This post is about a slightly non-conventional method to solve maritime problems.

We carried out our first successful design thinking workshop for maritime professionals on 06th March ’21.

As far as we know, this is a first of its kind in the world.

Maritime problems

In the Maritime fraternity, we often face problems that do not have a straight answer.

Listen to these statements. You must have heard them before!

- Recruitment Manager: We are not getting well trained juniors anymore!

- QSHE Superintendent: We are getting numerous Port state deficiencies on our vessels!

- Captain: No matter how many times you train everyone on board on how to start the emergency generator, they will always fumble in front of a Port State Inspector!

- Chief Engineer: How do we maintain the rest hours if we keep getting alarms at night at least twice a week?

Some are solved with temporary solutions, while some are left at that, after a casual discussion; in other words, we assume they cannot be solved and we have to live with them.

Let us look at it differently.

What is Design Thinking?

Design thinking is a branch of study that originated from the department of IDEO, at Stanford University, primarily pioneered by Professor David Kelly. It is a structured process to unleash our creative side and to help regular people come up with innovative solutions. We applied its principles to solve maritime problems with some amazing results.

Here is how it goes:

- First of all, we break down some psychological barriers and try to understand the end-user, and what needs to change.

- We then challenge assumptions, perceptions and even the most commonly accepted truths!

- Finally, we redefine problems to identify alternative strategies and solutions that might not be instantly apparent with our initial level of understanding.

In simple words, it is a different way to think about a problem.

Some of the world’s leading brands, such as Apple, Google, Samsung and GE, have rapidly adopted the Design Thinking approach in finding solutions to problems which do not have straight answers.

The mouse on your PC, as you see it today, is the brainchild of a design thinking workshop at Apple.

This workshop involved a specific process allowing the attendee to think of alternative non-obvious solutions. You could apply it to other maritime problems too, and it would usually emerge with a number of solutions that might surprise you.

The problem

What was the problem that we were trying to solve in this workshop?

We were on a vessel maintained at very high standards. Over the course of the last few months, they had noticed a certain trend.

In spite of elaborate training being carried out on board, even though all checklists and company procedures were being followed, the crew and officers were prone to making occasional mistakes that may have led to claims and other problems on the ship. As far as maritime problems go, this is quite a common one.

While the vessel remained compliant, every now and then you would find someone unable to reply to a Port State Inspector, or not following gangway procedures, or simply not wearing the proper PPE. This was not a regular occurrence, it was rare, but in this profession, even one such incident is not acceptable.

Clearly, increasing the training was not helping. In fact, there was no room to increase it anymore.

Was this a matter of individual interest, and should an action be taken against someone?

We found that when closely observed, such mistakes could be made by almost anyone on board! In other words, people who have made these mistakes are not necessarily making regular mistakes every day. They are aware of their jobs and aware of the requirements. Warning them individually or sacking them would not help.

So, the question we were trying to answer was:

How to devise the perfectly effective on-board training process?

Going for Specific Solutions

When we present maritime problems like these, most people have their standard suggestions. But we were not looking for generic answers like:

- We must carry out more training, or

- The people must pay more attention, or

- Identify and warn the individuals; or

- if that does not help, sack them!

Our aim was to find out what specific changes, must be made which will make the training stick to the attendee and so that they would be able to operate efficiently with zero errors. The changes may be for the trainee, the trainer, or the conditions under which the training is being carried out.

You may differ with me here, and say: “Oh, Zero-error is impossible!” Well, in that case:

Why not aim for perfection, and settle at excellence?

We were interested to see if the people on board had better ideas.

The core principles we used

Contrary to what you might think, we did not just ask everyone on board to give their own ideas. (Well, technically that’s what we did at first, just to prove how lame the initial ideas are…)

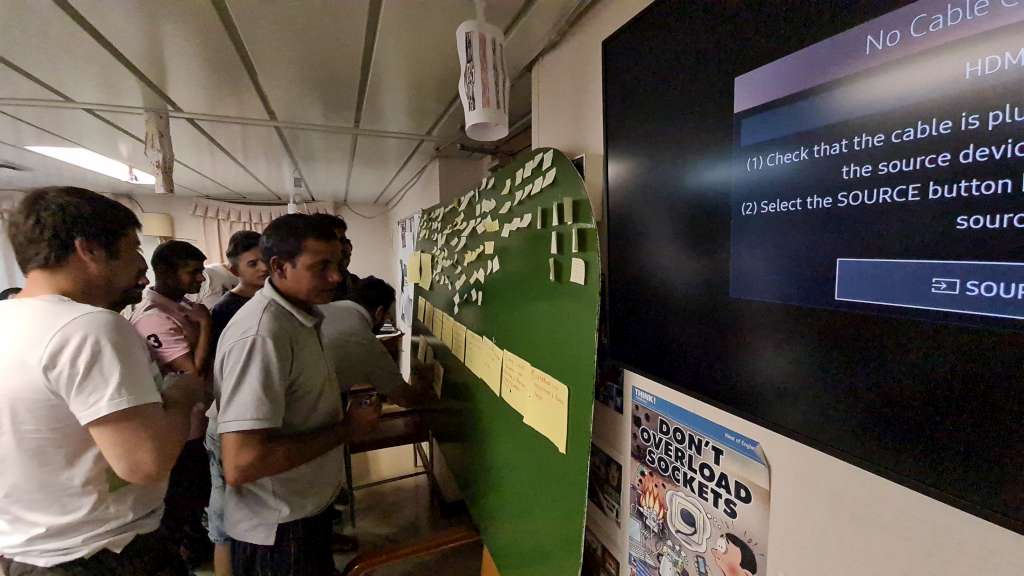

Every ship operates under a certain hierarchy.

People, in a closed room, are usually aware of the chain of command, even when asked to voice their opinions. They really cannot say anything that they feel. There are factors to consider. After all, they are sitting with their juniors and seniors with whom they have to work the very next day.

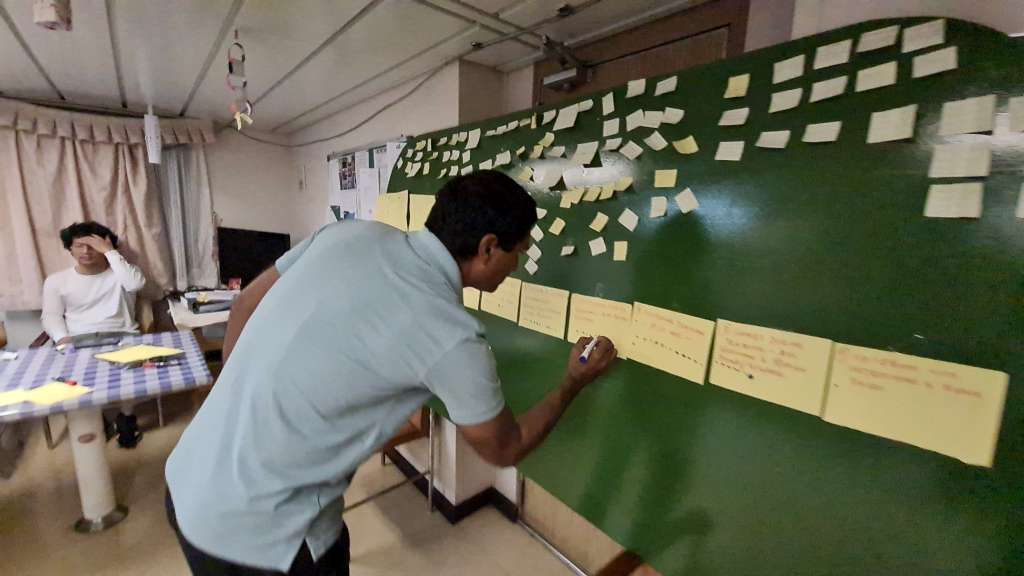

No, we did not start thinking about the problem like a room full of grave thinkers. In fact, a number of things we did in this four-hour workshop had nothing to do with the problem as such. It was a whole lot of fun!

A design thinking workshop, when properly conducted, helps bypass any barriers. People churn up ideas as they go along while being engaged and actively enjoying the session. It literally lets people open up without inhibitions and unleash their creative side.

I would not go into the details of it, you can get in touch with us for that, but it starts with simple interactive exercises. We call them ice breakers!

For example, at one point, we were asking people to imagine and draw a picture against a word, such as Home, or Smile. Everyone had a sticky note and a pen to draw. Think about it. If I asked you to imagine a picture against the word “Home” what would you draw? Some drew the picture of a house, while some sketched their family (a set of stick-figures holding hands), while for some, it was a can of beer. The quality of drawing did not matter, it was the content behind it that mattered.

What did we find?

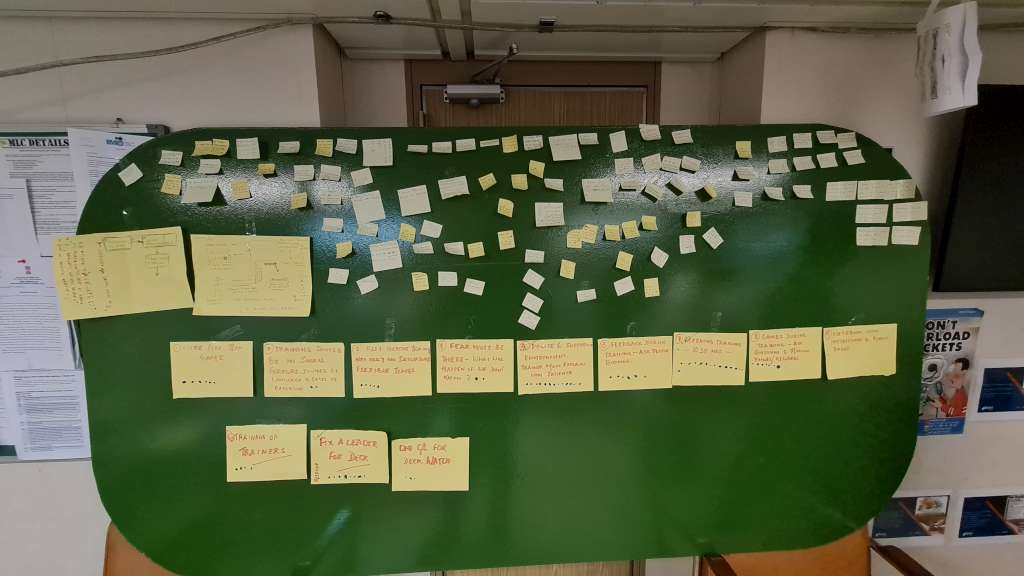

After a workshop that was carried out based on the core scientific principles advised by Prof David Kelly, the response was overwhelming.

We had pooled in over 105 new ideas from 24 crew members, which were shortlisted to a final 12, and then voted into a final three. What’s more, some of the brightest ones came from ratings and junior officers.

I am listing out all the final 12 ideas, in no particular order, here below.

Some of them may not be cost-effective, but they are worth pondering upon. These solutions have come from non-intimidated free-thinking seafarers and not from the conventional question-answer sessions or meetings.

The final list of ideas

To recap, the question was:

How to devise the perfectly effective on-board training process?

- Making an App: Certain common onboard training can be converted into an app, which anyone can play with a scoring system. The reward system would help generate interest.

- Training of Trainers: Trainers on board must be trained on how to make their training interesting. It is seen that some trainers can hold the attention span of the trainees higher than others. The principles of effective training must be understood by the trainers.

- Small Groups: Training must be carried out in small groups which must be divided on the basis of the level of expertise and language. Usually, the groups are divided randomly on board. However, if they are divided based on the expertise level, training may be more effective. Eg. Engineers may need less time to understand the Emergency Generator and more time for the Emergency Towing appliance than deck personnel. If divided by language, training may be carried out in a language more comfortable to the trainees.

- Fix a leader for Deck watch: Lapses happen during deck watchkeeping in port, even though people know what to do they still miss out. Eg. The firewire not being adjusted regularly, off-shore manifold gauges not checked, or the Manifold watch leaving the manifold to attend to the gangway. These may lead to claims/protests/deficiencies. The suggestion was to fix a leader for each deck watch, who would report to the duty officer and take charge of everyone else on deck. The leader can be rotated.

- A checklist for Deck watchkeepers: A short laminated checklist given to the deck watchkeeper (to the leader as above) will prevent missing out on the checks that need to be done during a cargo watch.

- Inform the consequences: People often think of it as normal to have forgotten part of the onboard training given. The common perception is everyone forgets, and many not very well aware of the consequences. Eg. If an officer could not demonstrate the starting of the Emergency Generator in front of an inspector, the ship may receive a deficiency which will then be cleared out by showing extra training, but how will it affect the officer or prevent others from forgetting on the next ship? Being made aware of how it can affect the individual might make people keener to follow.

- Morning training: Training to be carried out in the morning around 1030, when people are fresh, instead of 1530 or later when people are tired and mostly thinking of dinner.

- Games out of Training sessions: Questions can be asked after a certain training and a reward given to the person who can demonstrate the equipment without any errors. The prize can be as small as a chocolate bar, but the pride of receiving it in front of everyone else is enormous.

- A Notebook: The idea of having a notebook in the pocket is nothing new. However, the suggestion was for the company to provide a notebook that will have, in the first few pages, certain common things to refer to, as required on deck or engine room, related to safety and accident prevention. This can also be used to note down things that may be forgotten otherwise.

- Flexible times for training: People can be called in for five minutes during their deck or engine room work for quick training sessions by officers, as they are carrying out other maintenance jobs. This will be helpful for those who need individual attention. Groups training must be based on rest hours with certain groups given a separate time, instead of having everyone together.

- Supportive environment: An example was cited where a Chief Officer was patient to teach everyone individually the use of certain equipment which made everyone eventually an expert. This is in contrast with many others who resort to shouting and bad temper while carrying out training. It was clear that a supportive environment truly helps in creating a receptive atmosphere on board.

- Feedback during training sessions: More individual questions must be asked during the onboard training sessions to make sure it is effective. The training must never be a one-way discussion. This makes people get more involved and be in the moment instead of drifting off.

The follow-up

We had only one design thinking session on this vessel. While it brought out some interesting ideas, this would be far more effective if it could be repeated. What’s more, no one is ever bored in these workshops!

We passed on our results and requested the company to seriously consider running these suggestions through other vessels. Some of these ideas could then be implemented onboard as deemed suitable. They may bring about lasting change in the ability of Crew members to grasp the onboard training. After all, the problem in question is not just restricted to this vessel.

I would like to point out here, that almost every company appreciates a good idea, coming from anyone. There are even programs in place to reward such efforts!

The only new thing we did is to follow a process that guides them to come up with innovative thoughts.

Conclusion: Design thinking in Maritime Problems

You may wish to refer to my blog on the use of Creativity in the Maritime World and how it can help solve maritime problems.

What is a creative thought?

If you are good at problem-solving, you can perhaps relate to this: your ability to come up with a good solution where there are no straight answers is not just your intelligence! If you can churn up ten probable causes within an instant when you face a problem, there is creativity at the very core of it, that helps you bind your intelligence with your experience.

The problem is, this happens to you subconsciously, and you have no control over it. Those that do not have that power, also cannot help it. Design thinking is a process that can boost this ability consciously for people who do not have a natural problem-solving flare.

There is a very structured way to conduct a design thinking workshop. Wrongly done, it would not be effective.

This blog would not be sufficient to describe that, but feel free to Contact Us if you are interested. It can be used to solve maritime problems on ships and in offices, to bring out suggestions that would not normally come up. If the timeline can be stretched to a few days, larger problems can be tackled. That is the immediate benefit.

But there is another long term advantage here. When this process is repeated, it becomes a habit for the participants and the same people eventually become much better at solving their own day to day problems as well.

Worth a thought, isn’t it?